CHRISTCHURCH

03 379 4062

WELLINGTON

0800 277 822

INVERCARGILL

0800 277 822

Stack Electrical are industry leaders in hazardous areas, working for industry giants Exxon Mobil, Z Energy, BP… to name a few. We lead the way providing new installations and solutions for our clients.

Stack Electrical offer full turnkey solutions for our clients, from engineering, drawings, project management, installation, commissioning and then Inspection for compliance.

As compliance is such a crucial part of explosive atmospheres/hazardous areas, Stack Electrical keep up with all changes in compliance, with two hazardous area inspectors of our staff our clients can be sure that we will provide a quality and compliant installation.

At Stack Electrical, we understand the critical role that safety and efficiency play in your electrical systems. That's why we're proud to offer advanced Thermal Imaging Services for switchboards and equipment. Our cutting-edge technology and experienced team ensure that your electrical systems are operating at their best.

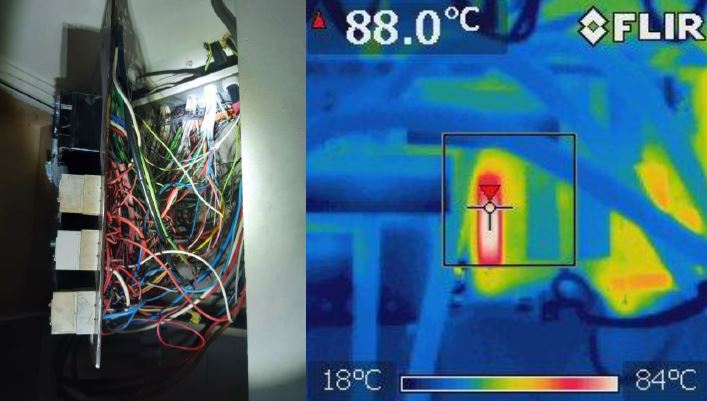

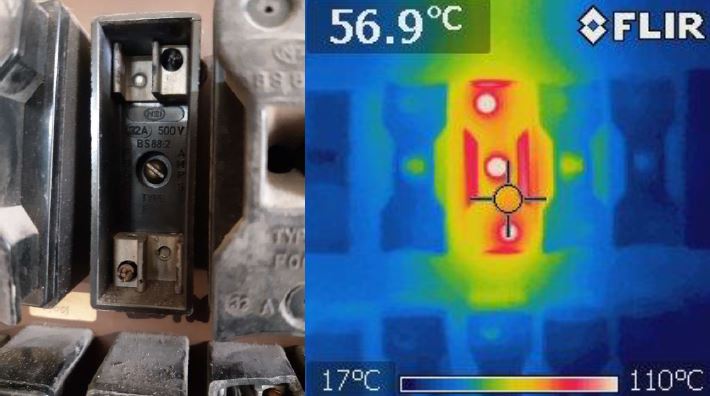

Thermal imaging is an indispensable tool for identifying potential issues within your electrical infrastructure before they become major problems. By detecting anomalies that can't be seen by the naked eye, we help prevent costly downtime, equipment damage, and safety hazards.

Our skilled technicians are equipped with state-of-the-art thermal imaging equipment and have the expertise to conduct thorough inspections of your switchboards and equipment. Whether you're in manufacturing, commercial, or industrial sectors, our team ensures that your electrical systems are running efficiently and safely.

Benefits of Thermal Imaging:

Our team conduct a comprehensive assessment of electrical systems, identifying areas that need attention. Using advanced thermal cameras, we capture high-resolution images of equipment, analysing temperature variations. Our experts then analyse the images to identify potential problem areas and provide actionable insights. Then we send out a detailed report with findings, images, and recommendations for necessary actions.

We are here to ensure systems meet the highest standards of operation, providing clients with peace of mind and confidence in their electrical infrastructure.

We have provided hundreds of solutions and new installations for client’s, we provide new installations as well as maintenance and works for compliance, we can offer full turnkey installations for spraybooths, mixing rooms and sandblasting rooms.

Stack Electrical also offer a 24 hour call out service for our hazardous area and industrial clients.

We provide project management services for large hazardous area installations. Stack Electrical have provided the electrical for new fuel storage facilities and maintenance for 30 years, our electricians are trained in explosive atmospheres to provide our clients with piece of mind and industry compliance.

Stack Electrical provide solutions for our LPG clients Rockgas, Gas Engineering Services, GASCO, Genesis among others. We provide new site tank installations and maintenance. We have the ability to provide our own gas detection systems to ensure the safety of our electricians and site personnel.

Call Stack Electrical for all your industrial and hazardous needs. You will be connected to one of our friendly experts to discuss your requirements or ask for advice.

When Tasman Fuels were selecting the main electrical contractor for their new terminal build in Timaru, they wanted a company with proven hazardous area expertise and a track record to match. They chose Stack Electrical.

“Stack Electrical were the main electrical contractor on our new Terminal build in Timaru. The Hazardous Area expertise Stack brought to the project was instrumental to a successful, timely and professional completion of the Oil terminal project” says Steve Simpson, Terminal Manager for Tasman Fuels

For Tasman Fuels the electrical installation of their large scale port fuel storage facility was important, especially for a new company entering the South Island market. Stack Electrical’s project included:

The project was a success and Tasman Fuels continues to work with Stack Electrical, valuing their relationship:

“The ongoing relationship with Stack Electrical in the form of maintenance, testing and project work has ensured the terminal is meeting its goals in compliance, operational safety and efficiency.

This has all been achieved with an “can do” attitude and professional working relationship between Stack Electricals’ staff and the terminal staff.”

Steve Simpson, Terminal Manager, Tasman Fuels

Z Energy owns and manages nearly 200 service stations, about 160 truck stops supported by pipelines, terminals and bulk storage terminal infrastructure around New Zealand. Their Lyttelton terminal is a key cog in their infrastructure wheel. Stack Electrical have a long history of hazardous project & maintenance work at the Z Lyttelton Terminal.

The most recent project completed by Stack Electrical at the terminal was additive radar installations for tank level indication. It’s specialised work and Stack Electrical are one of the very few firms capable of doing so. Project scope included:

Stack Electrical’s long history of hazardous area work Z Energy across New Zealand includes airport site lighting upgrades, numerous site camera installations, new PLC upgrade project at Lyttelton, and electrical upgrades for airport fuelling hydrant. In 2023 they will start hydrocarbon detection installations at both Lyttelton and Seaview.

“It's always a pleasure to deal with Stack Electrical. They are extremely professional, have great communication skills and provide high quality work. Highly recommend Stack Electrical for electrical work.”

Brendan Allcorn, Terminal Manager, Z Energy

New Zealand Oil Services new Gas Detection Systems project at their Lyttelton terminal was complex. It required the installation of 31 vapour and toxic detection units and needed to be completed on time to the highest standard without incidents. According to Jamie Cross, Terminal Operations Manager:

“Being a Major Hazard Facility, we must have the best contractors working on our site and Stack Electrical are the best.”

Project scope for Stack Electrical included the installation of gas detection system mounting and cabling, and the installation and commissioning of gas detection units

“ Being a Major Hazard Facility we must have the best contractors working on our site and Stack Electrical are the best.

They have recently just completed a complex project installing 31 vapour and toxic detection units at our facility which was completed on time to the highest standard and without incidents.

I wouldn’t use anyone else but Stack Electrical”

Jamie Cross, Terminal Operations Manager, NZ Oil Services